Formlabs

Digital Transformation Made Accessible

The Formlabs precise, reliable ecosystem takes the guesswork out of dental fabrication so faster workflows are just a few clicks away.

Formlabs adapted stereolithography (SLA) 3D printing technology to the desktop in 2011 and has since become the market leader for professionals, selling more than 100,000 desktop and large-format resin printers as of today.

Highlights at a glance

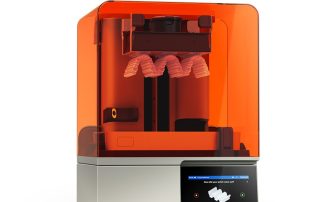

Form 4 – More Smiles, All Around

Form 4 is a blazing fast masked SLA 3D printer that combines an industry-leading materials library with a reliable, accurate print engine. Turn your ideas into reality faster than ever with easy workflows, leading reliability, and stunning part quality using the Form 4 ecosystem.

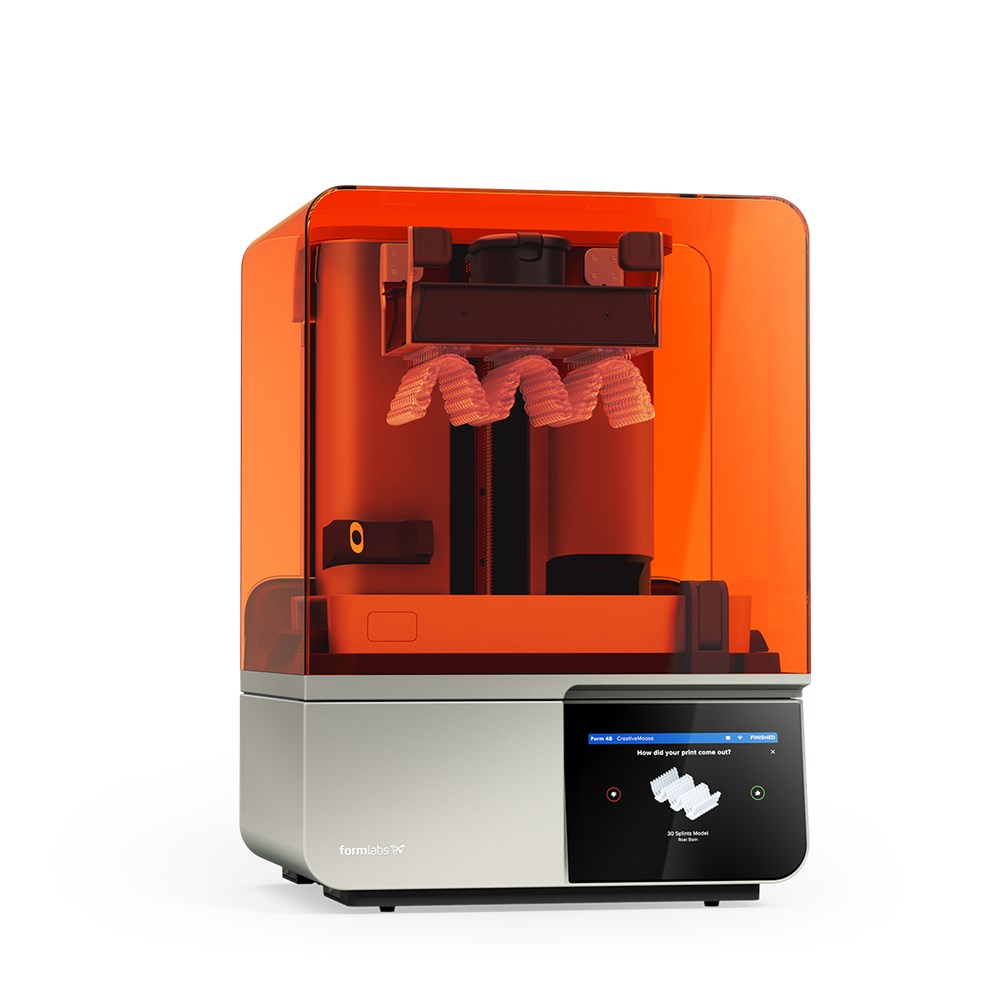

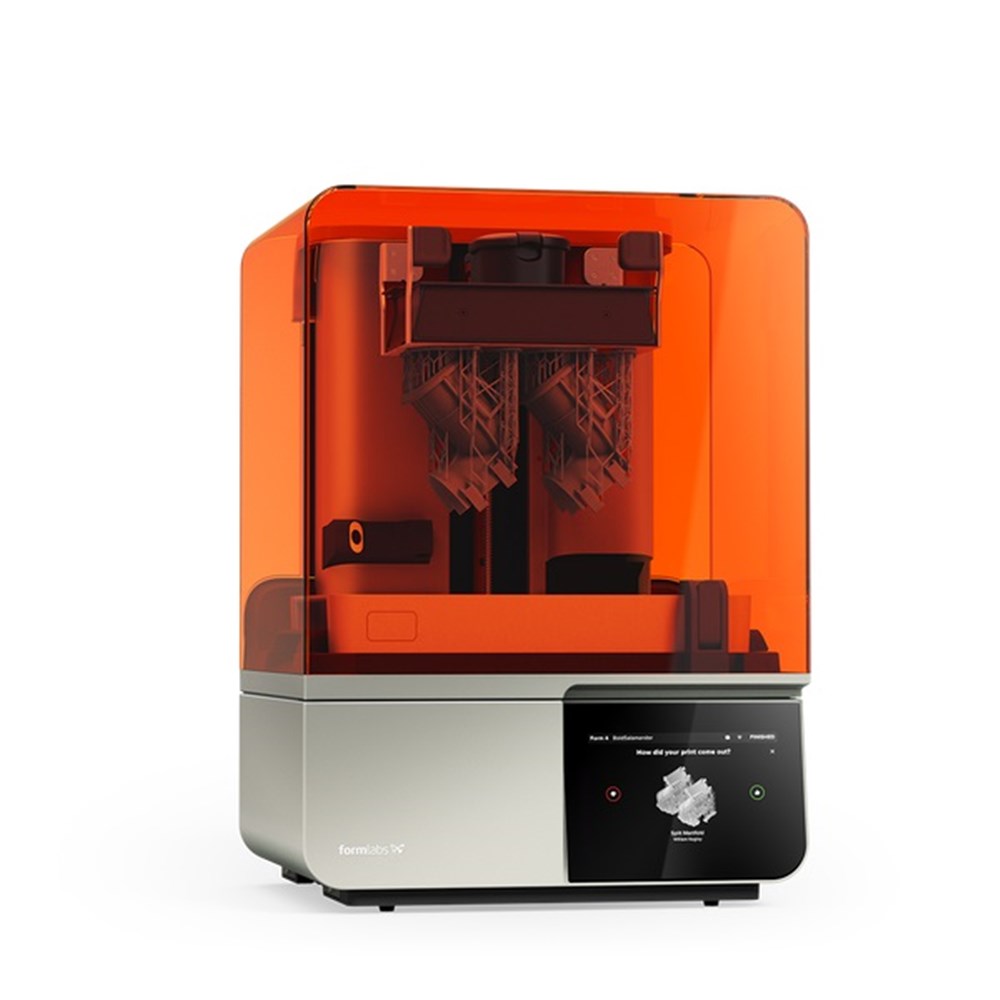

Form 4B – Blazing speed meets unmatched accuracy

Form 4B’s speed is driven by Formlabs’ new Low Force Display Print Engine, a powerful combination of ultra-high power LEDs, collimating lenses, optical filters, and a robust liquid crystal display. Together they cure each layer of resin rapidly — regardless of part size or quantity. With consistent surface accuracy, models, appliances, and prosthetics will fit every time.

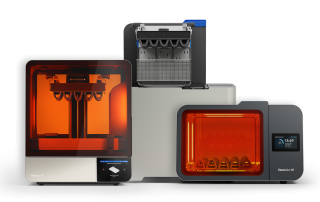

Form 4BL – A New Era of Dental Manufacturing

Form 4BL is a blazing fast large-format dental 3D printer that offers the most diverse materials library for dentistry and orthodontics. Create high-quality dental models and biocompatible appliances fast, with easy workflows, leading reliability, and stunning part quality using the Form 4BL ecosystem.

Form 4BL’s speed is driven by Formlabs’ new Low Force Display Print Engine, a powerful combination of ultra-high power LEDs, collimating lenses, optical filters, and a robust liquid crystal display. Together they cure each layer of resin rapidly — regardless of part size or quantity. With consistent surface accuracy, models, appliances, and prosthetics will fit every time.

Form Wash (2nd Generation) – Set it and Forget it

Form Wash (2nd Generation) automatically cleans printed parts thoroughly and efficiently with IPA or alternative solvents. Keep parts directly on the Build Platform as you transition them from the printer to Form Wash, or remove parts and place them in the wash basket. Parts are precisely and thoroughly agitated in solvent with an impeller, getting every nook and cranny perfectly clean, automatically for the appropriate time. When washing completes, the Form Wash automatically raises parts out of the IPA so they can air dry.

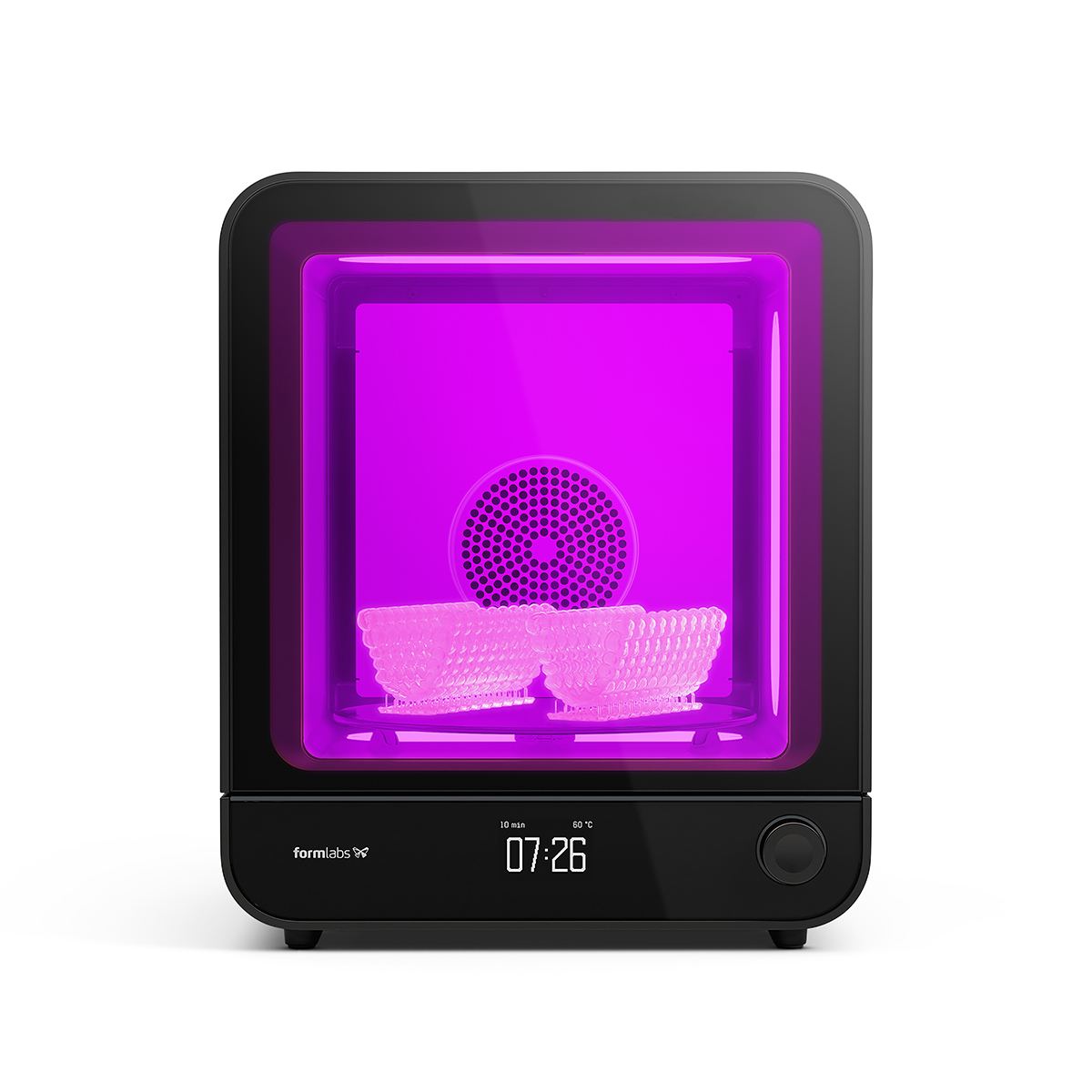

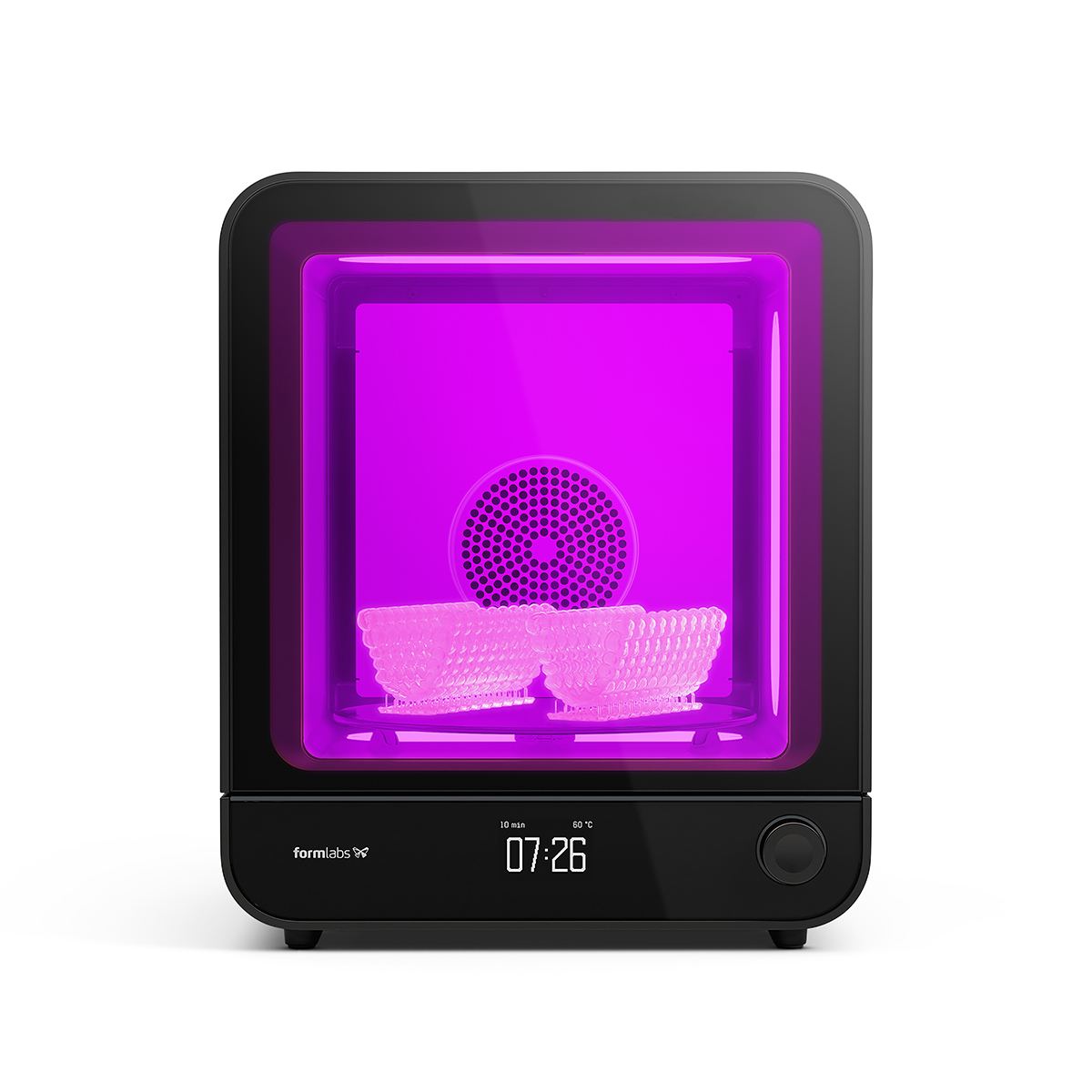

Form Cure (2nd Generation) – Blazing Fast Curing

Form Cure (2nd Generation) precisely combines heat and 405 nm light to deliver tough, strong prints with unprecedented speed and consistency. Now you can post-cure Form 4/B/L prints in as little as 60 seconds, with 4x more UV power, 5x faster heat-up times, and a 1.3x larger chamber. To begin curing, just select a validated preset for Formlabs 45+ materials. Advanced users can customise time and temperature to fit their specific needs.

Dental Resins – High-Accuracy 3D Printing Materials for Dental Labs and Practices

Formlabs Dental Resins empower dental labs and practices to rapidly manufacture biocompatible surgical guides, splints, fixed patterns and models, clear aligner models and full dentures.